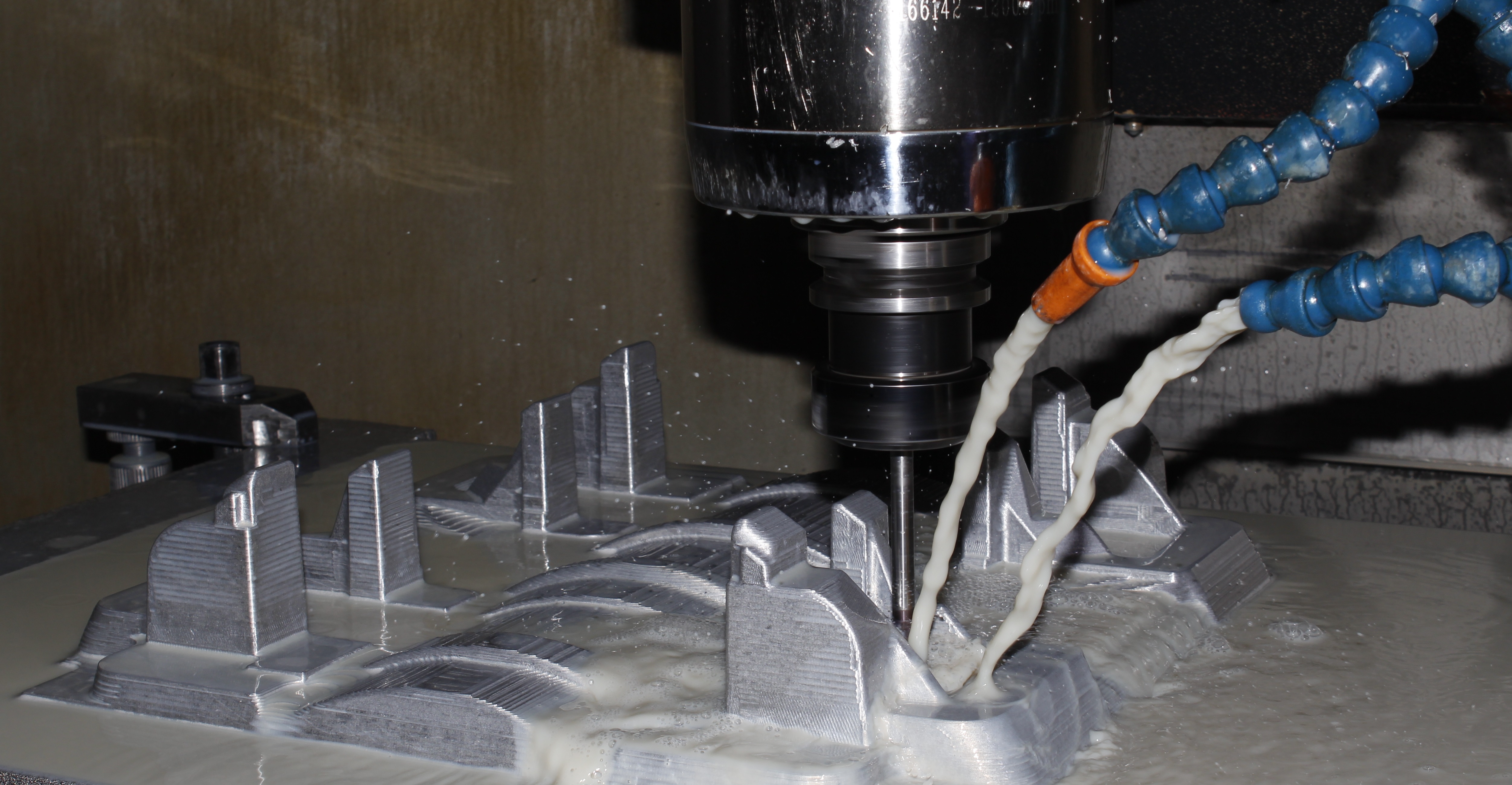

Pattern shop produces adequate pattern, utilizing the latest CAD / CAM – technology, responsible for the first and most important step of iron casting process. At the casting planning stage, the necessary simulations are applied by using programs like Magma, Novacast and NovaFlow & Solid CV ™. In this manner, the most economical production method can be calculated. Based on the design, the patterns are produced by in-house machining centers or using conventional manufacturing techniques. In the pattern shop, there are Vertical machining centers and CNC routers, model measuring instruments and equipment to machine Wood and Aluminum material required for the pattern.